I've never been one for small aspirations. As a kid, if they told me to build a model building out of paper, I was

going to use the longest, thinnest paper available and hold the thing together by sheer force of will. After college, I

wanted to work in science museum, so I picked the best one I knew of, got an (unpaid) internship, and flew

across the country to start working two months later. When I decided to learn to snowboard, I took the ski lift to

the top of the bunny slope, strapped in, eavesdropped on a kids' lesson to learn how to stand up, and went off to

go snowboarding.

anything else I've tackled so far. I want to make a wooden clock.

(from *before* it was popular, thankyouverymuch ) and a serious penchant for little

fiddly projects. I think precision makes things beautiful, and if you've ever seen the inside of a mechanical

watch, you'll know that it's been precision-ed to death. So, a clock it is. Wooden because metalwork is a little

beyond me right now and besides, look at this thing. It's gorgeous. This particular one is done by an immensely talented woodworker named Wayne Sutter.

great amateur project, doesn't it?

Clocks from the inside out

Initial impression: Holy crap, there's a lot of vocab here. Right off, we have: mainspring, arbor, going

barrel, ratchet, pawl, pinion, wheel train, escapement, remontoire, and balance wheel, just to name a few.

going to use the longest, thinnest paper available and hold the thing together by sheer force of will. After college, I

wanted to work in science museum, so I picked the best one I knew of, got an (unpaid) internship, and flew

across the country to start working two months later. When I decided to learn to snowboard, I took the ski lift to

the top of the bunny slope, strapped in, eavesdropped on a kids' lesson to learn how to stand up, and went off to

go snowboarding.

I mention this because I know my own tendencies, and I suspect that my next project is beyond the scope of

anything else I've tackled so far. I want to make a wooden clock.

I chose a gear for my first SketchUp tutorial for a reason. I have a major soft spot for anything clockwork

(

fiddly projects. I think precision makes things beautiful, and if you've ever seen the inside of a mechanical

watch, you'll know that it's been precision-ed to death. So, a clock it is. Wooden because metalwork is a little

beyond me right now and besides, look at this thing. It's gorgeous. This particular one is done by an immensely talented woodworker named Wayne Sutter.

|

| This is gorgeous, and it's not even finished in this shot. Go buy a clock from him - we need more craftspeople like this. |

Clocks, especially mechanical ones, are amazing and complex works of careful engineering. Sounds like a

great amateur project, doesn't it?

|

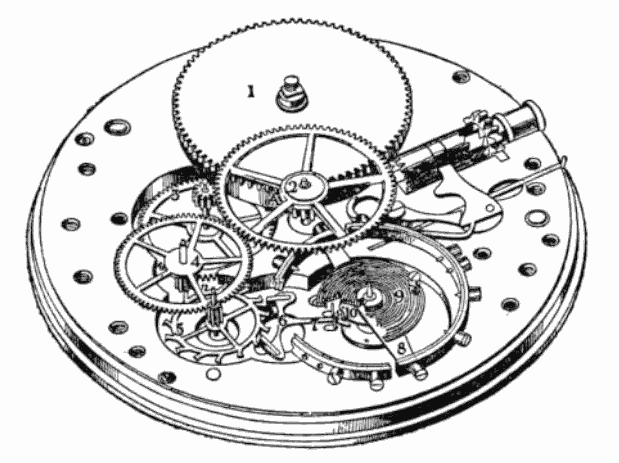

| Image from Wikimedia Commons. Yay public domain! |

Clocks from the inside out

Initial impression: Holy crap, there's a lot of vocab here. Right off, we have: mainspring, arbor, going

barrel, ratchet, pawl, pinion, wheel train, escapement, remontoire, and balance wheel, just to name a few.

From a mechanical perspective, I think that the easiest way to tackle a watch movement (the whole thing in the back of a clock or watch that makes the thing go) is to trace the energy. Energy goes into the watch when you wind it, and out of it as the stored energy is expended in making the hands turn and the escapement oscillate (and the alarm go, and the cuckoo bird cuckoo, etc.). When you wind a watch, you spin a post, or turn a key that turns a post, called an arbor. The arbor connects to a spiraling strip of metal called the mainspring.

|

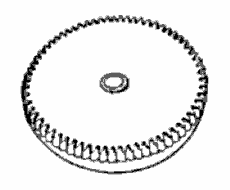

| The mainspring. Image from Wikimedia Commons. |

The mainspring is attached to the arbor from the inside of the spiral, making the whole thing look a little like a spinning top, or maybe a barred galaxy if you're creative.

The other end end of the mainspring attaches to a short, fat cylinder called the going barrel.

|

| Also Wikimedia. |

The barrel is free to spin, which is a good thing, because the barrel cylinder is capped with what is essentially a solid gear. This gear is used to interact with the gear train, which is the bit that makes the hands and other useful parts move. Its most important function, though is to power the balance, the little wheel that does for a wristwatch what a pendulum does for a grandfather clock.

|

| A real-life example: the going barrel in this watch is capped by the gear you can see in this picture. It also happens to be upside down. |

That's where rest of the gear train comes in. That'll have to wait for part two, though. In the meantime, here's some watch porn for all you horologists out there.

...that even sounds dirty.

No comments:

Post a Comment